Of course, this transformation wasn’t an overnight affair. Chris and buddies Jim Hansen and Rick Cote spent the better part of three years cutting, fitting, and modifying the Beetle to accept the numerous modifications they were endeavoring to make.

After the first few quick stops from double the double-nickel speeds, a glaring deficiency in the vehicle’s braking was discovered, but not before it resulted in totally smoked brake shoes and warped drums.

Munk’s Motors Discovers TURBONIUM

Motivated by 240 horses of Turbo Corvair

This article originally appeared in a 1984 article of VW & Porsche Magazine.

The folks around the city of Detroit, Michigan, have always been known for their affinity for automobiles, which is natural considering the automobile industry is the bread and butter for the majority of the city’s inhabitants.

For every year since the Muscle Car era began (most agree it was in the early ’60s, but some claim its roots date back to the ’50s or earlier), performance-oriented Michiganders have been tinkering in their garages and shops to make whatever the factories are currently offering just that much better, faster, and more “trick”. For the most part, that entailed working on American cars: those big block Chevelles, Hemi ‘Cudas, and 427 Corvettes that became the essence of street performance. The undisputed kings of the boulevard.

What’s happened to those same Michiganders within the past few years, however, is a spark of interest in a brand of automobile not necessarily completely American. We call these cars Volkswagen Beetles.

Of course, you can’t expect those good ol’ hot rodders to leave the original powerplant intact, can you? Self proclaimed “motorheads” like Chris “Chipmunk” Braden have trashed the venerable, flat-opposed four banger for more traditional American forms of motivation. And with marvelous results.

We call this phenomenon “The Detroit Look,” and, in Braden’s case, it refers to stuffing a 180hp turbocharged Chevy Corvair six cylinder into the engine compartment of his ’73 Super Beetle.

Of course, this transformation wasn’t an overnight affair. Chris and buddies Jim Hansen and Rick Cote spent the better part of three years cutting, fitting, and modifying the Beetle to accept the numerous modifications they were endeavoring to make. But, Chris is no stranger to Hi-Po VW’s. Over the past dozen or so years, he has owned 12 VW buses (the second one turbo ‘Vair powered), a ’69 Ghia convertible with 140hp Corvair engine, plus numerous Beetles (one powered by another 140hp Corvair). What all this tells us is that Chris is fanatical about alternatively powered VWs, which is just fine by us.

This particular Super Beetle is trick from stem to stern. However, having served previous duty as someone’s commuter car, the poor ol’ Bug was suffering from a severe case of Michigan rustover on the fenders and other panels. Structurally, however, the car was sound, but Chris and friends spent plenty of hours cutting, welding, and repairing the cancerous areas. Once the body was up to snuff, the “motorheads” went to work on the suspension.

Their goals were to have a vehicle capable of tight handling, a smooth ride with reasonable noise levels, and total absence of the typical VW “wheel hop.” All of this was remarkably achieved by the installation of 3-inch adjustable dropped struts with Bilstein inserts, Delrin stock replaced the factory rubber as track arm bushings, and polyurethane for the rear torsion bar bushings. A Scat anti-sway bar was used in the rear, while Gabriel Hi-Jackers allow adjustment for various degrees of firmness.

The motorheads constructed a rear subframe unit to tie the flexible body components together and triangulate weak areas, so the car’s weight and torque of all those cubes could be effectively carried. Predictably, all wheel hop and front mount problem ceased (the front mount no longer supports the load, and the car has been run without it), and no twist in the car’s tail has been noticed.

After the first few quick stops from double the double-nickel speeds, a glaring deficiency in the vehicle’s braking was discovered, but not before it resulted in totally smoked brake shoes and warped drums. The situation was remedied, however, by manufacturing disc brake adapters which mount Type III calipers to the spindles, then allowing Type IV rotors as a direct bolt-on. Modulation was achieved with a Kelsey Hayes proportioning valve neatly tucked away under the trunk mat for easy access. Chris tells us his next job is replacing the stock rear drums with Type III units.

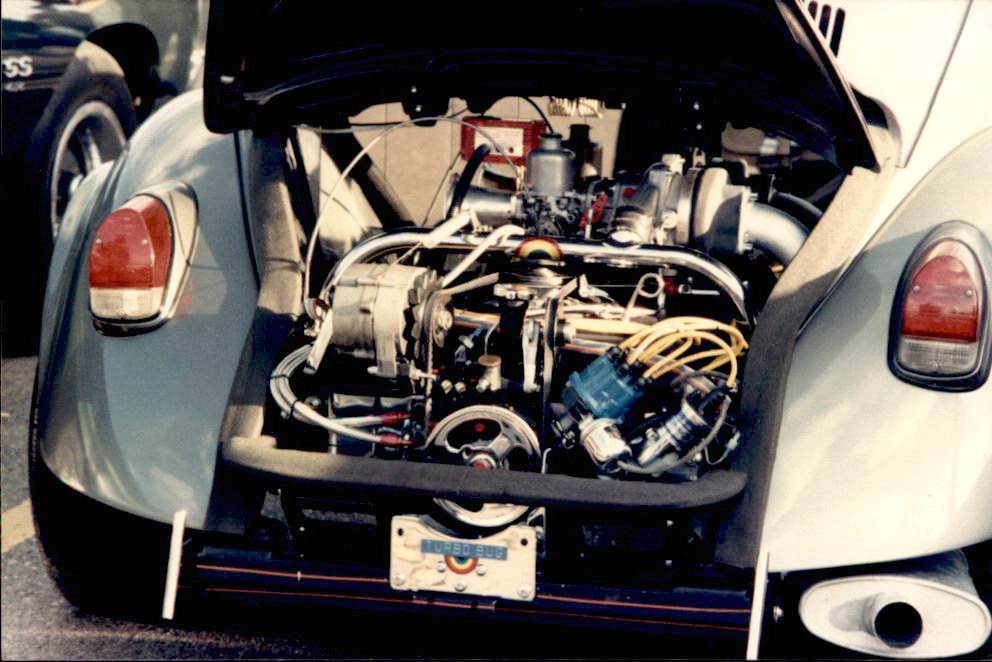

The powerplant of this wild Beetle started life as a 180hp Corvair Corsa unit, but has been modified to spin in reverse (clockwise) for use in the VW. A Crown 5050B reverse rotation cam was utilized in the potent rebuild, along with 0.060 over TRW forged pistons, 6.5 pound aluminum fly-wheel, SU “Turbo carb” by Riviera Engineering, high volume oil pump, distributor advance kit, plus a special adapter plate to mate the engine to the VW tranny. The motor’s stock heads and bottom end are sufficient for this relatively “mild” application of turbo assistance, which is a total of 15 PSI when using aviation fuel, and a regulated 9 PSI with pump gas, while a Spearco wastegate and Edelbrock VaraJection water injection system assure everything runs as planned. When the auxiliary fuel tank is stocked with 106 octane, a seat-mounted switch disconnects all boost controls for maximum thrust. Current horsepower is between 210 to 240.

The clutch plate is a 2700 pound Kennedy Maximum unit, and connects to a beefed transmission featuring chrome moly shift forks, close ratio third gear, Ghia ring and pinion and a cast iron side cover and through studs.

The not-quite-stock exterior includes subtle rear fender flares, shaving of front and rear bumpers, blacking out of chrome trim, and installation of ’72 Beetle tail lamps, plus Rabbit sidemarkers in the front grille work to serve as turn signals. 1978 Corvette “Silver Anniversary” charcoal grey paint covers the body.

Interior treatments includes a custom-built rear storage area where the back seat used to be, grey carpet work by Elaine Braden, a Grant wood rimmed steering wheel (with Corvair turbo insignia for the horn button), a variety of VDO engine monitoring gauges, hidden Sanyo lOO watt stereo with 4″ Pioneer door speakers and 6×9″s in the rear boxes, and the all important dash-mounted radar detector. Seating areas are covered in supple black velour and vinyl.

In addition to his friends, wife Elaine, and father, Chris wishes to thank Detroit disc jockey “The Electrifying Mojo” for supplying the motorheads with inspirational rock and roll during the numerous late night thrashes. Looks as though it paid off well.